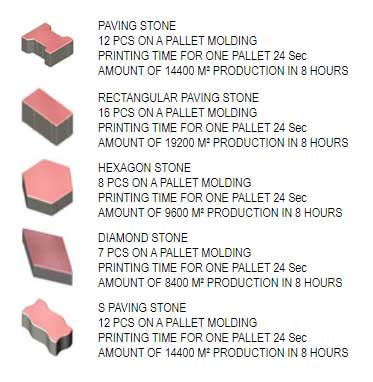

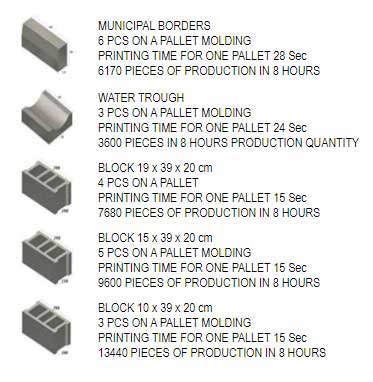

They are machines operating with hydraulic system in the pressure range of 120-200 bar. It is a machine that produces 4 pieces of 20 * 40 * 20 CM standard briquettes and 12 paving stones. Printing pallets are required for production. The concrete pressed in the molds is pressed on the pallets. Products produced in the same way are left to dry on the printing pallets..

EFF3 class electric motors Free spare parts with machine

2 + 2 total 4 years warranty

Compliance with the ISO 9001: 2008 total quality management system

CE Declaration of conformity with European norms

"HIGHLINE" product models with trained personnel

Fast service and spare parts assurance

Material use according to DIN and TSEK norms

Easy selection of programs

Auto / Manual selection freedom

Authorization certificate at the end of the training period

Stopping, holding and resuming

Forklift transport option

Internet troubleshooting option

Compliance with low voltages directive

.

SEMI AUTOMATIC

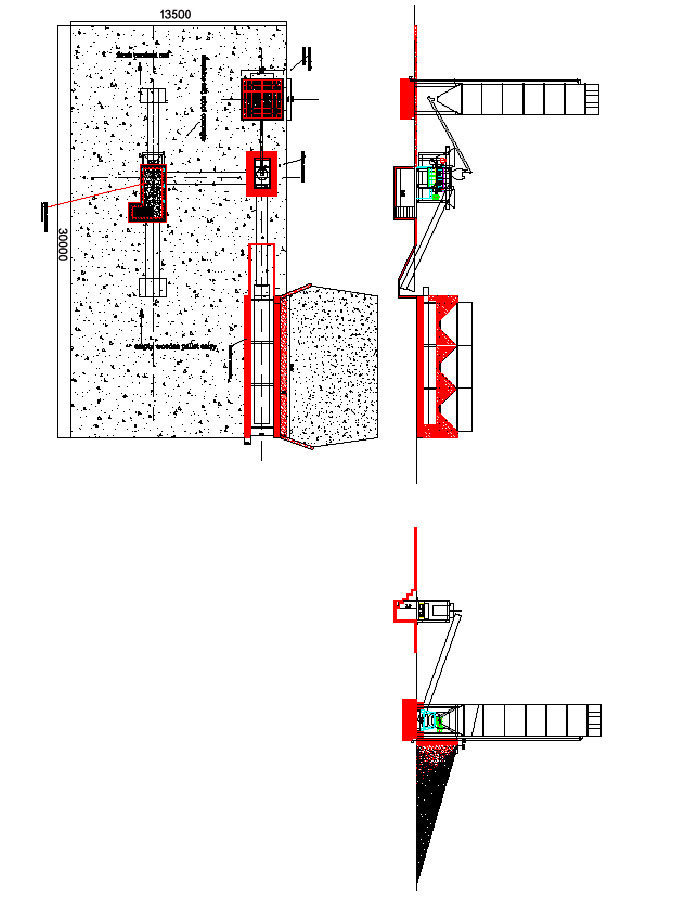

Area required for semi-automatic systems: Minimum 3000 m2 (300 m2 for machinery and equipment, drying area 1500 m2, dry ready storage area 700 m2, aggregate storage area 400 m2, empty pallet holding area 100 m2) The total transformer or generator power required to be installed in semi-automatic systems must be 80 kVA. The installed capacity is 50 kw. Number of personnel required to operate the factory in semi-automatic systems: 9 people (2 operator and 1 wooden pallet drive, 3 fresh product carriers, 3 aggregate feeders).

FULL AUTOMATIC

The required plant area in automatic systems: Minimum 3000 m2 (400 m2 for machinery and equipment, drying area 1300 m2, dry ready storage area 800 m2, aggregate storage area 400 m2, empty pallet holding area 100 m2) The total transformer or generator power required to be installed in automated systems must be 100 kVA. The installed capacity is 75 kw. Number of personnel required to operate the factory in automatic systems: 3 people (2 operator and 1 forklift driver).

GENERAL INFORMATION ABOUT THE AREA TO BE ESTABLISHED

NOVAL INC. the machine, empty pallet holding and fresh product drying area in order to protect from bad weather conditions to establish a minimum 600 m2 closed area is recommended. The buyer should prepare the concrete infrastructure of the area where the factory will be installed. NOVAL INC. prepare a detailed measurement plan for the area where the infrastructure will be established. The quality of concrete and the loads that it will carry, namely the static calculation and the strength of the reinforced concrete structure, must be carefully calculated and prepared by civil engineers. The electrical installation up to the control panel of the factory belongs to the receiver. It is necessary to have water plant and compressed air compressor and installation to the mixer unit of the factory. In order to start the installation, concrete, aggregate, plumbing and water, concrete suitable for the concrete project, at least 500 lt capacity compressed air compressor, forklift, bucket, telescopic crane with at least 10 tons lifting capacity, power and distributor electrical panel with the desired power and operators will be ready to operate the equipment. The environment appropriate to occupational health and safety rules for personnel assigned by the seller at the time of installation (electrical and electrical equipment with a grounding and isolation, machine and machinery with safe and suitable hand tools, secure scaffolding and platforms, etc.). and occupational safety equipment (helmet, steel toe cap and soles, rubber shoes, non-conductive rubber shoes, seat belt suitable for working in high places, etc.) to be ready and to observe the work done in this installation in terms of occupational health and safety and to control the resulting negativity as soon as possible.

.